Hornsea Project TWO chose Peak Pipe Systems innovative ClearDuct HDPE electrical cable ducting for the second phase of the world largest offshore wind farm. Located off the Lincolnshire coast in the East of England, the project consists of over 400 wind turbines, covering more than 1,564 square kilometres off the North Sea and is the world’s largest offshore wind farm, providing low carbon power to over one million homes.

Ensuring the safe and effective transmission of the wind turbines generated electricity was a key part of the project’s delivery. Peak’s innovative ClearDuct was an ideal choice for the host conduit duct to house and protect the multi-million-pound high voltage cables which carry the electricity generated by the colossal turbines that is transmitted to the national grid.

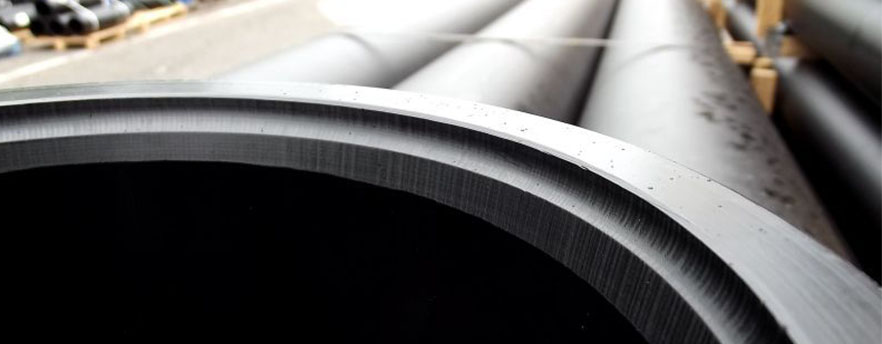

Over 50 kilometres of Peak’s ClearDuct HDPE electrical cable ducting was supplied throughout the project. ClearDuct has a unique design that ensures a damage-free solution to the cable and eliminates the potential for overheating. The unique machined pipe end design means that the internal fusion bead which is created during the high integrity welding process is recessed into the pipe wall, unlike conventional butt fusion welding. This guarantees no protrusion of the bead into the internal bore of the pipe, leaving cables with an unobstructed insertion path and no potential snagging points. Peak have created bespoke welding parameters which resulted in more than a 50% reduced weld cycle time, resulting in vastly increased welding productivity. The efficiency of the ClearDuct product doubles the volume of welds that can be achieved in the same time it takes to complete using conventional welding parameters.

Peak Pipe Systems worked on the project in partnership with Eco-Drill. Dino Cancellara, Director of GD Hire and subcontractor for Eco-Drill commented “I used the ClearDuct pipe on the Hornsea wind farm project, it was the first time I had used this product and was very impressed with the presentation and design of the product. It was easy to install and lining up the markings to ensure consistent welding quality was very straightforward. This product doubled our finished pipe output in a day and the design meant no debeading is required which also meant production efficiency was improved massively. I would recommend this product for future installs.”

If you’re working on a large project that features a large amount of electrical cable and are looking for ECD solutions, please get in touch: +44 (0) 1246 262 702 | sales@peakpipesystems.com